-

Development status of PVC industry in Southeast Asia07 13,2021

Development status of PVC industry in Southeast Asia07 13,2021In 2020, PVC production capacity in Southeast Asia will account for 4% of global PVC production capacity, with the main production capacity coming from Thailand and Indonesia. The production capacity of these two countries will account for 76% of the total production capacity in Southeast Asia. It is estimated that by 2023, PVC consumption in Southeast Asia will reach 3.1 million tons. In the past five years, the import of PVC in Southeast Asia has increased significantly, from a net export destination to a net import destination. It is expected that the net import area will continue to be maintained in the future.

-

Domestic PVC data released in November12 22,2020

Domestic PVC data released in November12 22,2020The latest data shows that in November 2020, domestic PVC production increased by 11.9% compared with the same period last year. PVC companies have completed the overhaul, some new installations in coastal areas have been put into production, the industry operating rate has increased, the domestic PVC market is trending well, and the monthly output has increased significantly. .

-

PVC market prices continue to rise12 07,2020

PVC market prices continue to rise12 07,2020Recently, the domestic PVC market has increased significantly. After the National Day, the logistics and transportation of chemical raw materials were blocked, downstream processing companies were insufficient to arrive, and purchasing enthusiasm increased. At the same time, the pre-sale volume of PVC companies has increased significantly, the offer is positive, and the supply of goods is tight, forming the main support for the market to rise rapidly.

-

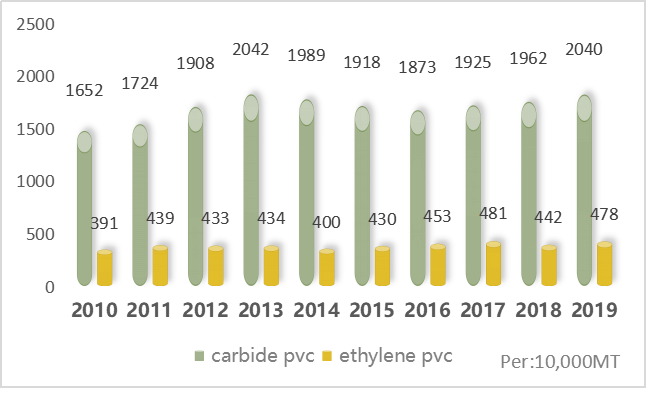

Comparision of China's two PVC production capactities-Chemdo organized09 29,2020

Comparision of China's two PVC production capactities-Chemdo organized09 29,2020Domestic large-scale calcium carbide PVC production enterprises vigorously promote the development strategy of circular economy, enlarge and strengthen the industrial chain with calcium carbide PVC as the core, and strive to build a large-scale industrial cluster integrating "coal-electricity-salt". At present, the sources of vinyl vinyl products in China are developing in a diversified direction, which has also opened up a new path for the procurement of raw materials for the PVC industry. Domestic coal-to-olefins, methanol-to-olefins, ethane-to-ethylene and other modern processes have made the supply of ethylene more abundant.