-

PVC Paste Resin Market .01 03,2023

PVC Paste Resin Market .01 03,2023Rise in Demand for Construction Products to Drive Global PVC Paste Resin Market Increasing demand for cost-effective construction materials in developing countries is estimated to boost the demand for PVC paste resin in these countries in the next few years. Construction materials based on PVC paste resin are replacing other conventional materials such as wood, concrete, clay, and metal. These products are easy to install, resistant to changes in climate, and less expensive and lighter in weight than the conventional materials. They also offer various advantages in terms of performance. Increase in the number of technological research and development programs related to low-cost construction materials, especially in developing countries, is anticipated to propel the consumption of PVC paste resin during the forecast period Consumption of PVC paste resin is expected to increase in the next few years, due to rising demand for lightweight automobiles in developing countries such as India. Governments of these countries are taking initiatives to increase the usage of electric vehicles to reduce carbon emissions. Manufacturers are looking for materials that would help reduce weight, thickness, and volume of automobile components, without harming the structural integrity and functionality of a vehicle. Electric vehicles are lightweight than the conventional automobiles and they have higher energy efficiency. PVC paste resin is significantly consumed to manufacture electric vehicles. Emulsion Process Segment to Witness Lucrative Growth Based on the manufacturing process, the global PVC paste resin market has been segmented into emulsion process and micro-suspension process Emulsion process is anticipated to be the leading segment of the global PVC paste resin market during the forecast period. The emulsion process is preferred for the manufacture of finer PVC materials. Demand for superior-quality PVC materials has been increasing among consumers. This is likely to provide lucrative opportunities to the emulsion process segment of the global PVC paste resin market during the forecast period. High K-value Grade Segment to Hold a Significant Share of Global PVC Paste Resin Market Based on grade, the global PVC paste resin market can be divided into high K-value grade, mid K-value grade, low K-value grade, vinyl acetate copolymer grade, and blend resin grade The high K-value grade segment is anticipated to hold a major market share during the forecast period. PVC paste resin of high K-value grade is suitable in the production of high-quality coatings and flooring materials. PVC paste resin has the ability to withstand moisture and it has good tensile strength. This is another factor driving the global PVC paste resin market. Construction Segment to Hold a Leading Share of Global PVC Paste Resin Market Based on application, the global PVC paste resin market can be classified into automotive, construction, electrical & electronics, medical & healthcare, packaging, and others PVC paste resin is suitable for floor coating due to its resistance to moisture, oil, and chemicals Rise in infrastructure development activities in developing countries is driving the demand for PVC paste resin in the construction segment. This, in turn, is driving the global PVC paste resin market. Automobile is expected to be the second-largest application segment of the global market during the forecast period, followed by electrical & electronics, medical & healthcare, and packaging segments. PVC paste resin is widely used in the manufacture of medical gloves, due to its good tensile strength. Asia Pacific to Hold a Major Share of Global PVC Paste Resin Market In terms of region, the global PVC paste resin market can be segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa Asia Pacific is estimated to account for a prominent share of the global PVC paste resin market between 2019 and 2027, owing to rise in the demand for inexpensive and lighter construction materials. Growing urbanization and rising construction activities in developing countries in the region, such as China, India, Malaysia, and Indonesia, are likely to boost the PVC paste resin market in Asia Pacific during the forecast period. Rising demand for lightweight vehicles as well as leather-based products is driving the demand for PVC paste resin in Europe Key Players Operating in Global PVC Paste Resin Market The global PVC paste resin market is fragmented, with several regional and global manufacturers operating in the market. Prominent players operating in the global PVC paste resin market seek to enter into partnerships for the development of new applications of PVC paste resin.

-

The main uses of paste pvc resin.12 20,2022

The main uses of paste pvc resin.12 20,2022Polyvinyl chloride or PVC is a type of resin used in the production of rubber and plastic. PVC resin is available in white color and powder form. It is mixed with additives and plasticizers to manufacture PVC paste resin. PVC paste resin is used for coating, dipping, foaming, spray coating, and rotational forming. PVC paste resin is useful in the manufacturing of various value-added products such as floor and wall coverings, artificial leather, surface layers, gloves, and slush-molding products. Major end-user industries of PVC paste resin include construction, automobile, printing, synthetic leather, and industrial gloves. PVC paste resin is increasingly used in these industries, due to its enhanced physical properties, uniformity, high gloss, and shine. PVC paste resin can be customized as per the specifications of end-users. Furthermore, it exhibits high resistance to moisture and variations in temperature.

-

Methods to Enhance PVC Properties – Role of Additives.12 13,2022

Methods to Enhance PVC Properties – Role of Additives.12 13,2022PVC resin obtained from polymerization is extremely unstable due to its low thermal stability & high melt viscosity. It needs to be modified before processing into finished products. Its properties can be enhanced/modified by adding several additives, such as heat stabilizers, UV stabilizers, plasticizers, impact modifiers, fillers, flame retardants, pigments, etc. Selection of these additives to enhance polymer's properties is dependent on end application requirement. For example: 1.Plasticizers (Phthalates, Adipates, Trimellitate, etc.) are used as softening agents to enhance rheological as well mechanical performance (toughness, strength) of vinyl products by raising the temperature. Factors that affect the selection of plasticizers for vinyl polymer are:Polymer compatibility;low Volatility;cost. 2.PVC has a very low thermal stability and stabilizers help prevent degradation of polymer during processing or exposure to light. When subjected to heat, vinyl compounds initiate a self-accelerating dehydrochlorination reaction and these stabilizers neutralize the HCl produced enhancing the life of polymer. Factors to be considered while selecting heat stabilizer are: technical requirements;regulatory Approval;cost. 3.Fillers are added in PVC compounds for a variety of reasons. Today, a filler can be a true performance additive by delivering value in new and interesting ways at the lowest possible formulation cost. They help to: increase stiffness and strength,improve impact performance,add color, opacity and conductivity and more. Calcium carbonate, titanium dioxide, calcined clay, glass, talc etc. are common types of fillers used in PVC. 4.External lubricants are used to assist smooth passage of PVC melt through processing equipment. while internal lubricants reduce melt viscosity, prevent overheating and ensure good color of product. 5.Other additives like processing aids, impact modifiers, are added to enhance mechanical as well as surface properties of PVC.

-

What are the Characteristics of Polyvinyl Chloride (PVC)?12 01,2022

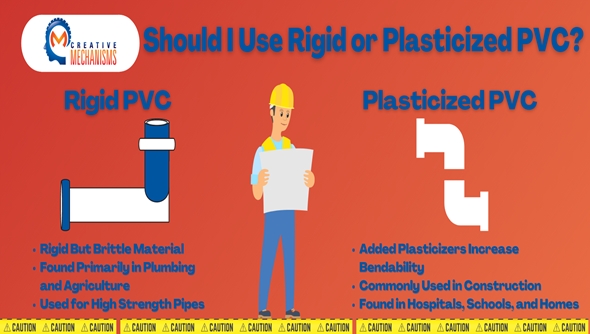

What are the Characteristics of Polyvinyl Chloride (PVC)?12 01,2022Some of the most significant properties of Polyvinyl Chloride (PVC) are: Density: PVC is very dense compared to most plastics (specific gravity around 1.4) Economics: PVC is readily available and cheap. Hardness: Rigid PVC ranks well for hardness and durability. Strength: Rigid PVC has excellent tensile strength. Polyvinyl Chloride is a "thermoplastic" (as opposed to "thermoset") material, which has to do with the way the plastic responds to heat. Thermoplastic materials become liquid at their melting point (a range for PVC between the very low 100 degrees Celsius and higher values like 260 degrees Celsius depending on the additives). A primary useful attribute about thermoplastics is that they can be heated to their melting point, cooled, and reheated again without significant degradation. Instead of burning, thermoplastics like polypropylene liquefy allows them to be easily injection molded and then subsequently recycled. By contrast, thermoset plastics can only be heated once (typically during the injection molding process). The first heating causes thermoset materials to set (similar to a 2-part epoxy), resulting in a chemical change that cannot be reversed. If you tried to heat a thermoset plastic to a high temperature a second time, it would only burn. This characteristic makes thermoset materials poor candidates for recycling. PVC offers a wide variety of applications and advantages across multiple industries in both its rigid and flexible forms. In particular, Rigid PVC possesses a high density for plastic, making it extremely hard and generally incredibly strong. It is also readily available and economical, which, combined with most plastics' long-lasting characteristics, makes it an easy choice for many industrial applications like construction. PVC has an extremely durable nature and lightweight, making it an attractive material for construction, plumbing, and other industrial applications. Additionally, its high chlorine content makes the material fire-resistant, another reason why it has gained such popularity across various industries.